Izinsiza zomshini wokugaya, sinemishini ehlukile yokunemba yokuyimboza. Umshini wokugaya ophathwayo we-gantry, umshini wokugaya ohambisanayo ophathwayo, umshini wokugaya ongukhiye, amamodeli ahlukahlukene ayatholakala emsebenzini wokugaya. Kungakhathaliseki ukuthi umshini wokugaya ama-eksisi amathathu, noma amathuluzi omshini wokugaya ama-eksisi angu-2 .

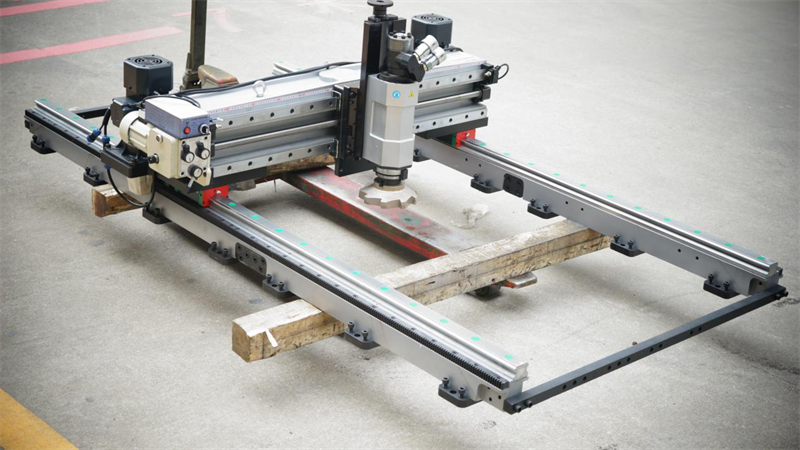

Umshini wokugaya we-gantry ophathwayo we-GMM2000 ungalungiswa cishe kunoma yisiphi isimo. Umzimba oyinhloko we-eksisi ye-Y eyenziwe nge-Aluminium , ingukukhanya okuphatheka kalula ngaphandle kokulahlekelwa ukuqina. I-X axis eyenziwe ngensimbi yesakhiwo, iqine ngokwanele futhi azinzile kusisekelo. Umbhede oqinile uyatholakala ukuze unwetshwe ngendlela ehlukile ngokuya ngenkundla.

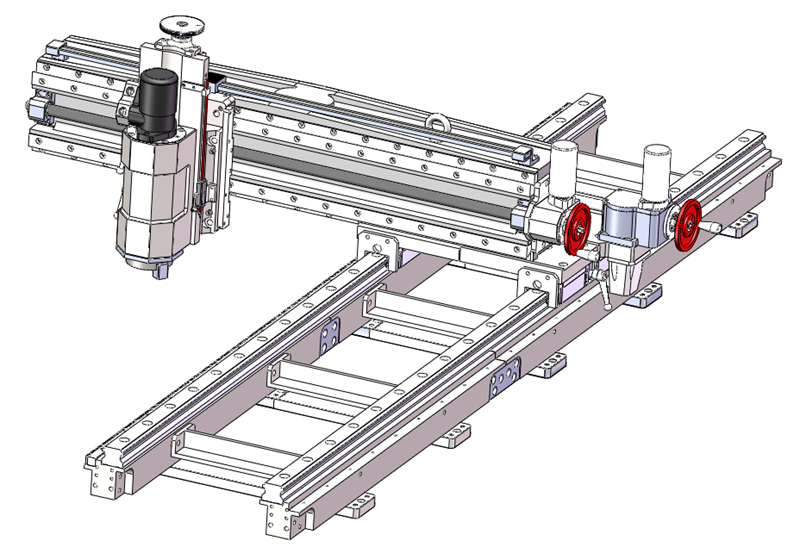

Imishini yokugaya ephathekayo iklanywe ngesistimu yesitimela ehlukanisiwe ukuze yenze kalula kokubili umugqa kanye ne-gantry milling enobuncane bokushintshwa.

Senze ngendlela oyifisayo imishini yokugaya ephathwayo encane efanayo. Eyomsebenzi wasendaweni, futhi iyaphatheka nemithwalo yokupakisha.

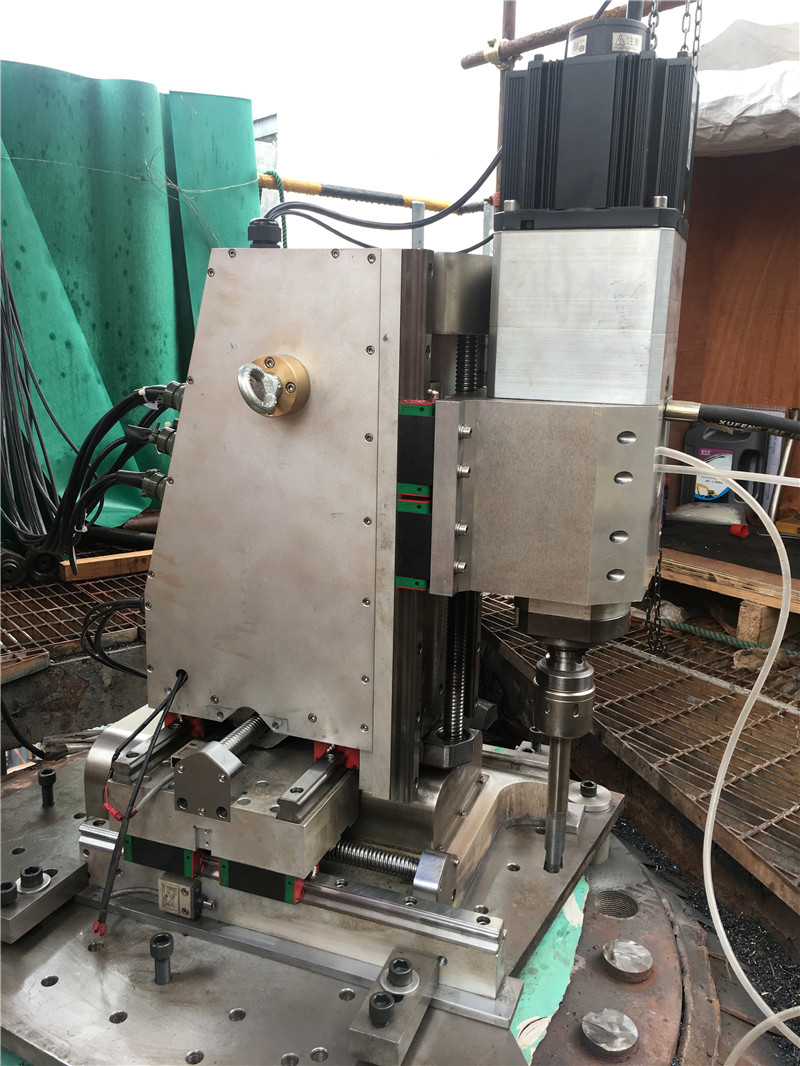

I-Weld shaver yobuhlalu enemodeli kagesi yamapuleti iyatholakala.

Ngomshini wokugunda ubuhlalu obushiselwe, ubungalungiswa epuletini noma ngamaketango epayipini. Umsebenzi ophathwayo we-gantry milling surface wenza ukuthi imishini yokushefa i-weld ibe compact, ilula ngaphandle kokulahlekelwa ukuqina.

Isetshenziselwa ukucubungula indiza yamapayipi, ukugaya i-seam ye-welding. Weld ukushefa ubuhlalu amapuleti. Ingasetshenziswa ekusetshenzisweni kwamadayimitha epayipi ahlukene noma ukucaciswa kwe-welding seam ehlukene. Kulula futhi kuyashesha, kungenziwa ngezifiso njengesicelo.

Imboni yethu izokwenza uzibuthe ukuthi ulungise isisekelo njengoba kudingeka kumathuluzi omshini wokugaya ophathwayo.

I-axis eyodwa, i-axis engu-2, imishini yokugaya ephathekayo ye-eksisi emi-3 iyatholakala kumathuluzi omshini wesayithi aletha ukubekezelelana kwendawo yokusebenzela. Esizeni amathuluzi omshini wokugaya ophathekayo angagxunyekwa phezu kwezinto zokusebenza ngezindlela eziningi ezahlukene kanye nezindawo eziningi, okuhlanganisa ukubholtha, izinsimbi zamaketanga, amapuleti omhlatshelo, ukushintsha omagnet noma njengoba kudingwa ngokuya ngezinto zokusebenza zesayithi.

Imishini yokugaya ephathekayo inika amandla ukugaya okunembayo, ukubhola, kanye nesicefe ukuthi kwenziwe ngokuphumelelayo ukuze kuhlangatshezwane nokubekezelelana okuqinile.

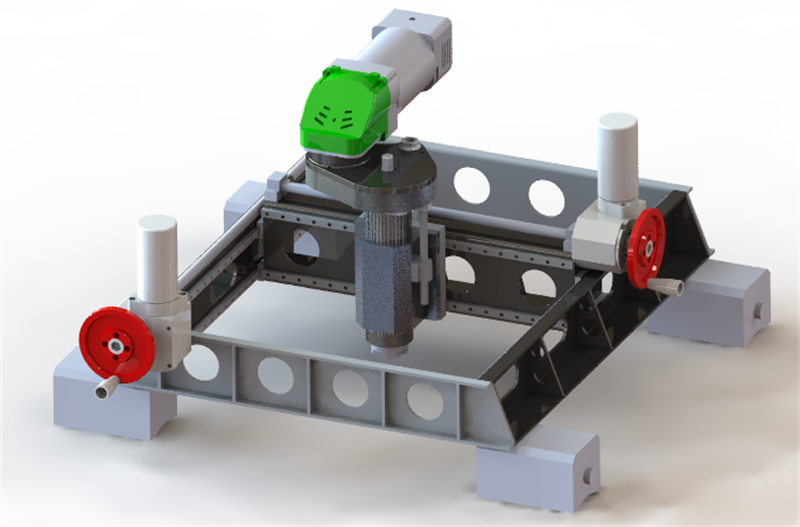

Ukuze kulungiswe i-flange esizeni, singenza umshini wokugaya we-cnc ukuthi wenze ukususwa kwe-stud, ukusika intambo.

Umshini wokugaya intambo we-CNC

Isicelo somshini wokugaya kawoyela, igesi kanye neKhemikhali, Izisetshenziswa Ezisindayo Zokukhiqiza Amandla, Ukwakhiwa komkhumbi nokulungisa

Izinhlelo zokusebenza ezijwayelekile:

• Ama-flange esistimu yamapayipi

• Ama-valve flange nama-bonnet flange

• Ama-flange okushintsha ukushisa

• Ama-flange omkhumbi

• Ubuso be-flange ezinhlelweni zamapayipi

• Amaflange ezindlu zamaphampu

• Ukulungiselela ukushisela

• Izinqwaba zeshidi lamashubhu.

• Izisekelo zokuthwala

• Amahabhu okugcina okushayela

• Ubuso begiya lezinkunzi

• Ukukhiqizwa kwempahla yezimayini

• Amasongo

• Izisekelo zokuthwala

• I-Crane pedestal flange.